The Power of Automation in Data Migration

Automation is a practical solution to speed up and optimize the entire data migration process

Despite all risk management efforts, enterprises must be prepared for events threatening the existence of the company. These events of existential impact are classified as crises and require extraordinary measures for business recovery and continuity. For severe events, cross-functional crisis management as the last ‘line of defense’ requires comprehensive involvement of the supply chain management team. This article outlines both the necessity as well as the key tasks to ensure supply chain crisis preparedness and management.

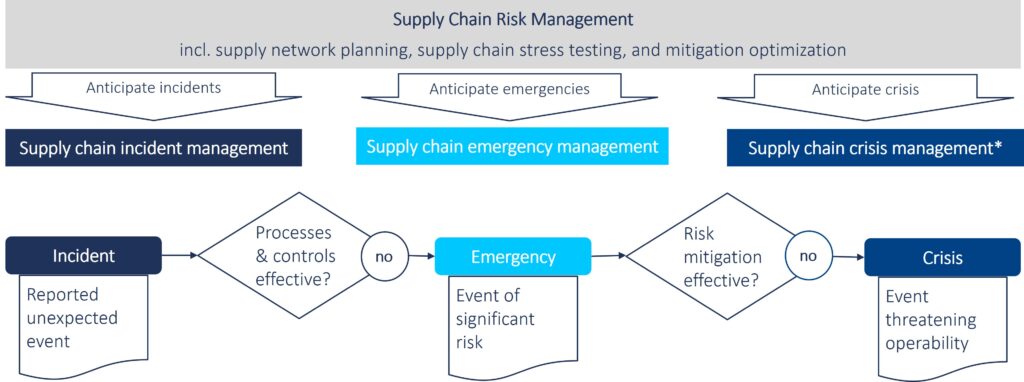

There are events with negative commercial or operational impact, that may be rated as a crisis by some functions since they cause much work, trouble, and concern. However, most of them will rather be classified either as an incident or as an emergency: Internal controls including corrective and preventive actions as well as business continuity measures are sufficient to cope with these event types.

In contrast, events leading to a crisis are threatening the existence of the whole company or the well-being of its customers, employees, or other people. Maximum management effort and attention is required as internal controls and procedures fail to mitigate the impact of the crisis (figure 1). Due to its severity, a crisis is in most cases jointly managed by all functions or departments to rescue people and businesses.

In the event of supply crises, supply chain management will therefore not act alone, but as one important player in the company’s crisis management bodies. Naturally, substantial supply disruptions need to be managed from different perspectives. Regardless of the cause, which may be an external raw material shortage or disruption of internal manufacturing operations. All steps and participants of the value chain, including the most important customer base, are subject to diligent crisis and business recovery management.

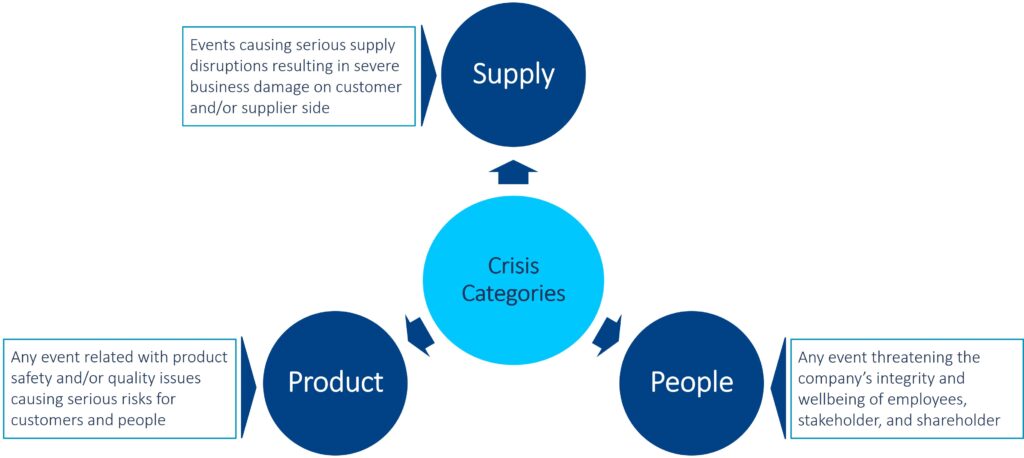

A crisis caused by either the product itself, e.g., in terms of safety and quality, or by the disruption of the product supply, is the category, for which supply chain management should always maintain the highest level of crisis preparedness (figure 2). Managing this type of crisis will take maximum management effort as supply processes fail and some mitigation measures are missing or might not be sufficient to effectively minimize the threat to the company. Instead, it is up to SCM to detect and declare a crisis. Perhaps also a force majeure, and consequently, request to immediately establish its company’s crisis management bodies. Figure 2 shows the categories, where supply chains could be the root cause of a crisis and where SCM will be a core function in the joint crisis management team to ensure business continuity and recovery.

Preparing the crisis management system means to establish procedures for early crisis detection and reporting as well as for managing the unexpected with a cross-functional team.

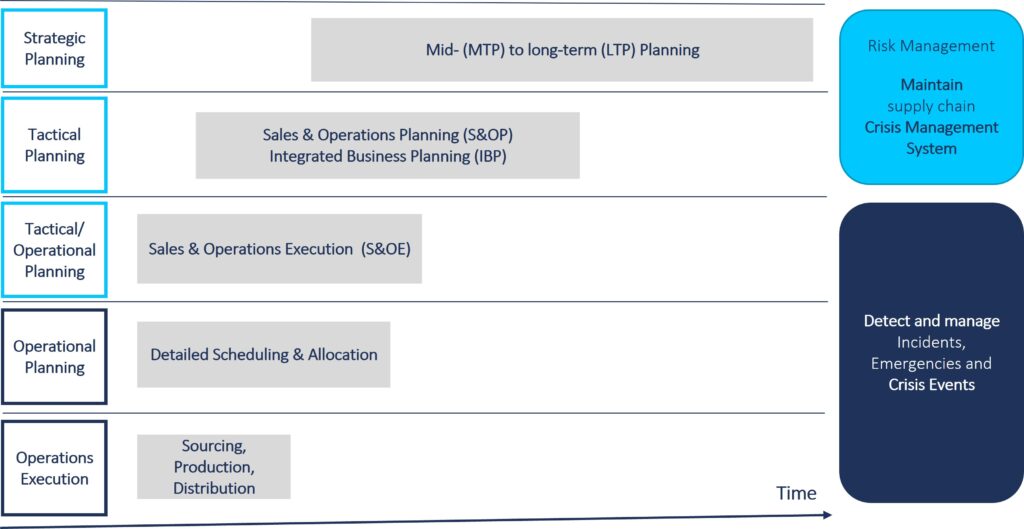

Naturally, supply chain crisis management is established on a long- to mid-term basis. If available, existing management bodies that already deal with risk management should be engaged to limit the efforts of onboarding and to avoid too many boards or boards. The closer the crisis board is to the area of risk management, the higher the awareness of the need to manage situations that can no longer be avoided by risk mitigation. Against this background, cross-functional decision-oriented IBP & SOP review meetings like the IBP management business review (MBR) might serve as an ideal collaboration place – and potential crisis management body – to define a crisis management team (CMT) that will prepare the crisis management system (CMS), see figure 3.

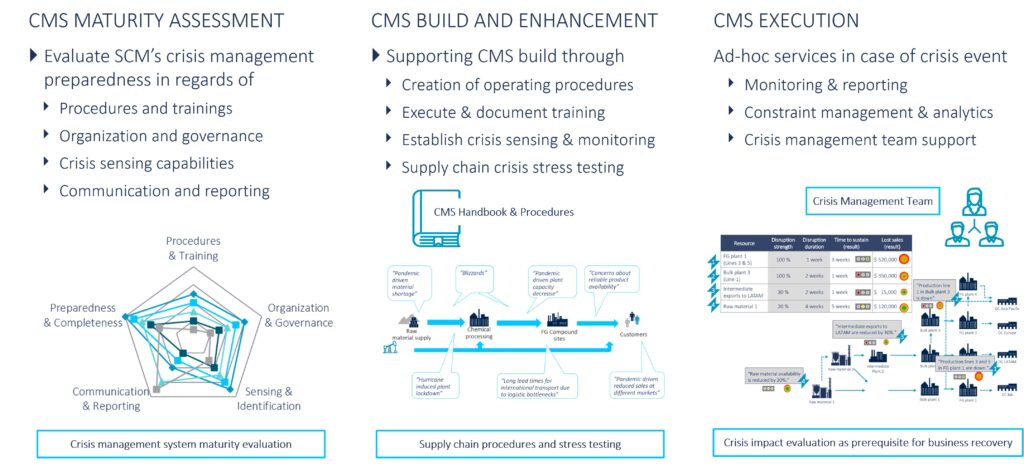

It is up to senior management, preferably the executive management board, to define the overall crisis organization and the crisis management team (CMT). Both will become effective as soon as a crisis has been identified and announced. Supply chain crisis management procedures regarding, among others, product recalls, business continuity measures, supplier and customer communication, and operations recovery should be prepared in close alignment with CMT and be endorsed by the executive management board. Most importantly, regular training and simulations are required to optimize procedures and their execution (figure 4).

For product supply-related incidents, crisis identification is a continuous task of supply chain and operations management. Diligent monitoring of internal and external parameters and events is a key prerequisite to timely detect a situation where, for instance, risk-mitigating buffer stocks or product substitution will fail to avoid severe damage to customers and/or the company. For complex operations in complex commercial ecosystems, Camelot recommends evaluating the potential of AI-based monitoring. This is a promising approach to detect unknown and unexpected incidents. And, since many companies consider longer-lasting IT system failures as a significant crisis root cause, reliable fallback systems and procedures for supply chain reporting and communication should always be installed.

As a member of the CMT, SCM will define actions and countermeasures during a product supply crisis. Respective supply chain crisis management procedures should include sufficient authorization and delegation on a functional level to ensure fast alignment and decision-making by the CMT. Executive management is continuously informed through the crisis management board and may also endorse critical decisions.

One, if not the most important element of a crisis management system is communication. This also applies to SCM: Communication is the first and permanent measure throughout the entire crisis to provide guidance to all concerned internal stakeholders as well as to all external customers and suppliers. Especially in times of substantial supply disruptions and/or product quality threats, fact-based communication will help customers and suppliers to better manage the impact on their business and to minimize reputational loss.

Fact-based communication can only be as good as data-driven SCM reporting. On the one hand, the extent and duration of a supply disruption or a product recall is essential information for all customers to anticipate stock-outs and, if possible, to timely substitute missing raw materials. On the other hand, internal continuous communication is a prerequisite not only to achieve the best alignment and efficient recovery but also to keep up the dedication and motivation of all employees.

Supply chain crisis management is a must-do for all SCM leaders. Consequently, in many companies, it is already a well-represented function in their crisis management system. In the following, we highlight some checkpoints to strengthen supply chain crisis management:

Check if the crisis management board, crisis management team, and all concerned units/employees are up-to-date and aware of respective roles and responsibilities. Both at the global/corporate level and at the country/regional level. Ensure that SCM as a key crisis management function is sufficiently represented in the crisis management system and its respective bodies (boards and teams).

Though a crisis cannot be directly anticipated (if so, risk management could immediately become effective and mitigate), a crisis management system can be established, in which all concerned functions are represented and acting. This system is defined through crisis procedures which cover, among other areas, governance, communication, incident detection and reporting, training, business continuity, and recovery measures.

The earlier a crisis event becomes visible, the faster the management and recovery will proceed. Therefore, the monitoring of the internal and external supply and operations indicators is a key prerequisite for adequate response, decision-making, and communication throughout the entire crisis phase. Given a complex business model and business environment, AI-based monitoring can help you sense incidents, emergencies, and crises early.

The crisis management system should be simple, easy to follow, and it should provide clear practical guidance as the crisis will cause a lot of uncertainty and confusion. Practicing the confrontation with the unexpected through crisis simulations (including the likely exposure to press and social media) is the only way to achieve optimal preparedness.

Diligent communication of data and information for internal and external (customers, vendors) decision-making is one of SCM’s core crisis management tasks. This requires capabilities for scenario-based comprehensive planning and reporting, and also close collaboration with sales and marketing serving as the communication (inter)face towards the customer.

Increasing end-to-end process automation and intelligence will further reduce supply chain management efforts. However, as soon as processes and procedures fail due to emergency and crisis incidents, supply chain planning and execution will be back in the hands (and brains) of supply chains. Bearing in mind that the manager’s first responsibility is to mitigate risks and ensure business continuity, SCM leaders and organizations will focus even more on the development and maintenance of their crisis and risk management systems.

For experienced organizations with a well-established crisis management system, it is generally not a big deal to adequately maintain all SCM-related CMS components as outlined in figure 4. However, if either a CMS is missing or SCM and operations have not been sufficiently involved in the current CMS, the preparation of supply chain crisis-related procedures, monitoring, reporting as well as organizational and communicational readiness is time-consuming and might even lack completeness.

In this case, a focused employment of consulting services bringing in outside-in views, best-practices-based templates, analytics, and accelerators will remove workload from the SCM team. Moreover, it shortens CMS implementation and ensures completeness and quality of all CMS-SCM components (figure. 5).

List of abbreviations

CMS Crisis Management System

CMT Crisis Management Team

SCM Supply Chain Management

S&OP Sales and Operations Planning

S&OE Sales and Execution Planning

IBP Integrated Business Planning

This paper is solely based on own experience and has been created without any support of AI tools like ChatGPT.

Automation is a practical solution to speed up and optimize the entire data migration process

Discover how you can streamline your financial master data management and reengineer financial processes with SAP MDG Finance.

Whilst it seems straightforward to carry out either a blood transfusion or a data migration, the actuality proves far more complex.

In this blog article, Camelot introduces you to the main principals of Demand-Driven Supply Chain Management.