The Power of Automation in Data Migration

Automation is a practical solution to speed up and optimize the entire data migration process

As we can currently see, sustainability requirements are increasing in all areas of business and private life. This is also a major topic for the textile retail trade with its numerous suppliers, a global production chain, and many challenges in terms of environmental and social responsibility. For small and medium-sized companies especially, improving sustainability without hampering daily business due to high reporting and controlling requirements can be a challenge.

The Mannheim-based textile retailer engelhorn already recognized that sustainability requires early, systematic, and determined action, especially when it comes to embedding aspects of ESG (environmental, social, and ethical considerations) in purchasing. As is the case with this topic in many small and medium-sized companies, it is a question of finding the right balance for engelhorn as well: How can sustainability be integrated into existing business processes as pragmatically as possible without causing major disruptions in daily business?

Founded in 1890, the Mannheim-based family business engelhorn offers high-quality fashion, accessories, shoes, sports fashion, and sporting goods across 38,000 square meters of space. Five restaurants complete the offering, including OPUS V, which has been awarded two Michelin stars. In addition to a fashion and a sports store, engelhorn has a store for lingerie and underwear, a store for socks and stockings, and a Tommy Hilfiger store in Mannheim city center. engelhorn also operates engelhorn active town, a store for outdoor goods, in Viernheim’s Rhein-Neckar-Zentrum. With over 950 brands, the e-shop engelhorn.de offers 24/7/365 shopping pleasure.

In recent years, engelhorn has already systematically worked on sustainability in their business operations, for example by implementing energy-saving measures in the stores and logistics (complete conversion to LED lighting), climate-neutral shipping, systematic reduction of returns, and reduction of packaging waste. After reducing energy consumption, emissions, and plastic waste in particular, the focus is now on the next step: systematically embedding sustainability in all purchasing processes. “The sustainable use of resources is becoming more and more important, and can even be vital for a company’s survival. That is why we are working to reduce our footprint. It involves a major effort, and we can positively influence this only together with our suppliers,” explains Simon Engelhorn, Managing Director at engelhorn.

With more than 1,000 suppliers and over 60,000 different articles in the women’s, men’s, and children’s clothing segment as well as shoes, accessories, and sporting goods, engelhorn’s purchasing department manages a wide range of products for its customers. From an ESG perspective, not only do the majority of CO2 emissions occur within the sphere of influence of purchasing (via the Scope 3 emissions caused by materials, clothing production, and transport). The commitment also includes environmentally and socially responsible manufacturing and supply chains, which will also be increasingly ensured and monitored by the new German Supply Chain Act (LkSG) from 2023/24 on.

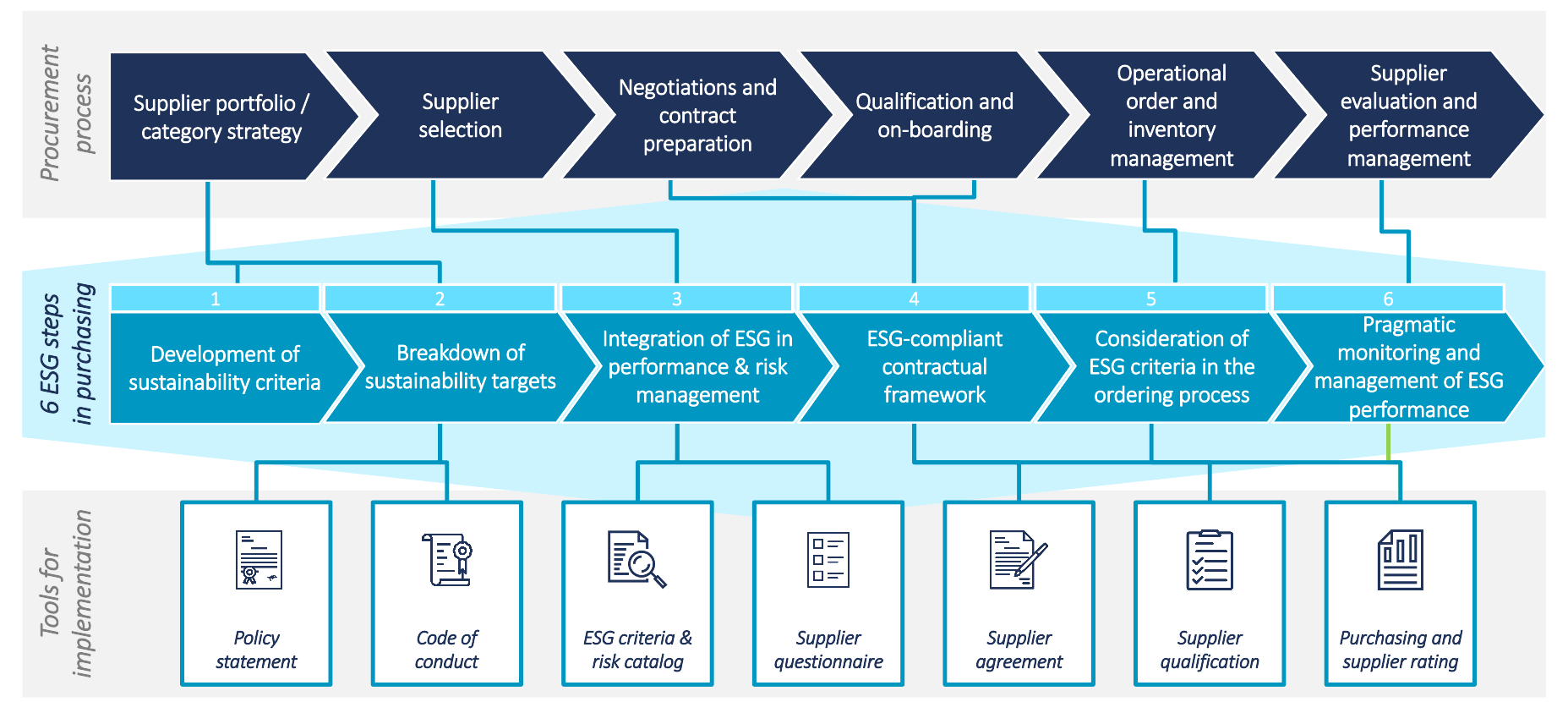

Consequently, engelhorn is now focusing on sustainable purchasing in a joint project with Camelot Management Consultants. As a leading consulting specialist for value chain management, Camelot helps companies to embed sustainability in value and supply chains. The consultants support clients like engelhorn in the redesign and reorganization of their processes, operating models, roles, and capabilities as well as their IT and data landscape. “The central question of our joint initiative was: how can ESG commitments be reliably and transparently incorporated into all procurement decisions – from the category strategy, negotiation, and contract design to supplier management? To do so, we make ESG standards binding in supplier agreements and transparently measure their implementation in the supplier rating,” explains Simon Engelhorn.

This goal was implemented in six pragmatic steps in a joint project with employees from Purchasing, Supplier Management, Controlling, and Sustainability (see figure 1). The focus was on deriving a self-contained sustainability toolbox from engelhorn’s purchasing strategy and quickly implementing it with suppliers. The most important building blocks:

“With this new approach, engelhorn is effectively and pragmatically integrating sustainability criteria into its purchasing and supplier management. This implements both legal and customer requirements and creates a good starting point for realizing further steps with regard to the Supply Chain Act from 2023/24,” confirms Thomas Ebel, Partner at Camelot Management Consultants.

“The first step has been taken; the concept and the plan are in place. Now it is a matter of implementing and realizing this process with the many suppliers,” emphasizes Simon Engelhorn.

Automation is a practical solution to speed up and optimize the entire data migration process

Discover how you can streamline your financial master data management and reengineer financial processes with SAP MDG Finance.

Whilst it seems straightforward to carry out either a blood transfusion or a data migration, the actuality proves far more complex.

In this blog article, Camelot introduces you to the main principals of Demand-Driven Supply Chain Management.