Supply Chain Management

How to transform your supply chain into a competitive advantage

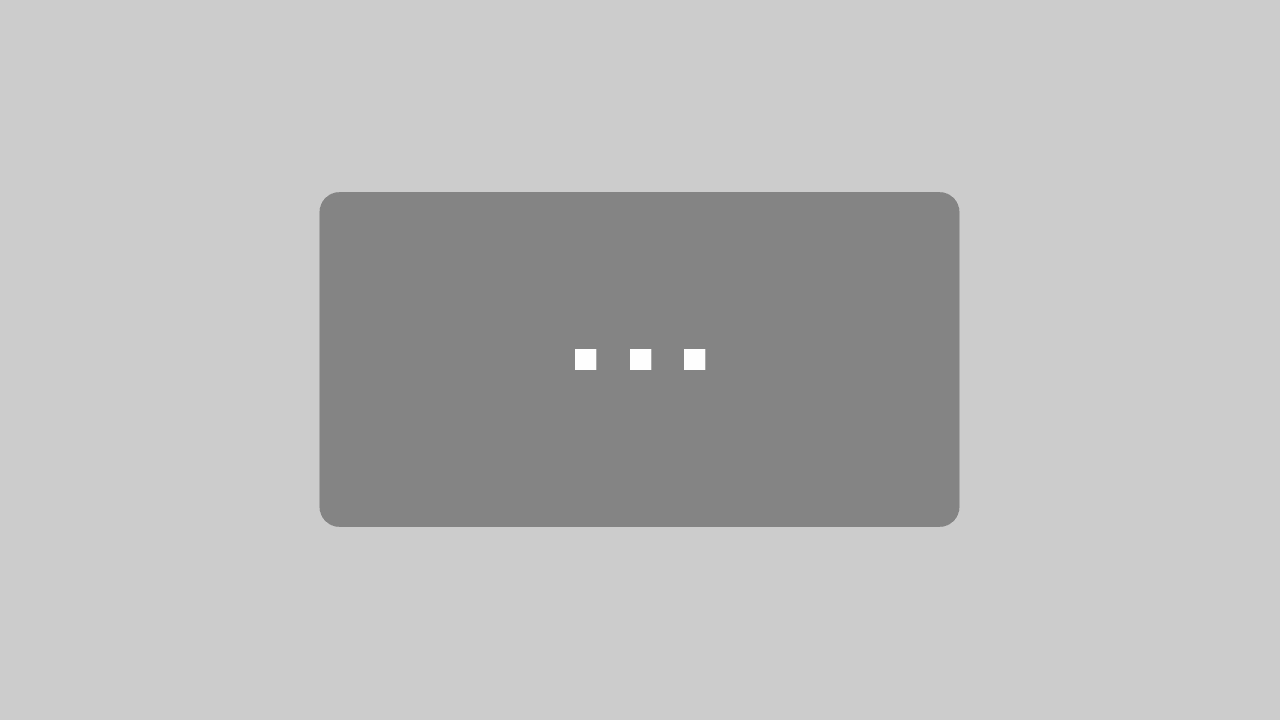

Mastering the unexpected

Supply chain leaders can’t avoid business uncertainty, but they can build resilient supply chains that drive profitability and growth in a disruptive reality.

How we help clients

Supply Chain Diagnostics

CAMELOT’s supply chain diagnostics approach is a structured supply chain scan to enable next-level SCM.

Supply Chain Design

Adaptive supply chain design is key to achieving the required levels of service, cost, risk, flexibility, and innovation.

Supply Chain Transformation

Transforming the supply chain from a cost factor into a real value engine enables a competitive edge and outstanding returns.

Supply Chain Analytics

With advanced supply chain analytics, we deliver the supply chain insights you need: descriptive, predictive, prescriptive.

Integrated Business Planning (IBP)

Helping clients embed Integrated Business Planning end-to-end in their organization. IBP is the evolution of S&OP.

Production Planning & Scheduling

Our experts support you in mastering complexity and volatility with sustainable, next-generation production planning. Arrange Callback

Procurement

CAMELOT’s procurement experts help clients accelerate the transformation of procurement into a value driver.

Distribution & Logistics

Meeting rising customer expectations requires new collaboration models and integrated, digital concepts in logistics.

Demand-Driven Supply Chain Management

We provide market-leading capabilities in Demand-Driven Supply Chain Management: from first undestanding to business impact.

CAMELOT Project Accelerators

Jumpstart your supply chain project with powerful data analyses and simulations through CAMELOT’s Analyzer Apps powered by Elixum.

Related Topics

German Supply Chain Due Diligence Act

How to implement the new regulations while taking the next step towards a sustainable value chain.

Digital Supply Chain Transformation

Explore the building blocks of the supply chain of the future.

Financial Supply Chain Integration

Supply chain leaders integrate financials into the decision-making process.

Our Ecosystem

At CAMELOT, we focus on aligning state-of-the-art system solutions with the specific needs of your industry. We take a client-centered approach, analyzing your requirements without bias towards any particular technology. Our expertise is bolstered by top-tier partnerships with leading technology providers, guaranteeing you access to the newest innovations customized to meet your strategic objectives.

SAP

As the market leader in enterprise application software, SAP is helping companies of all sizes and in all industries run better by redefining ERP and creating networks of intelligent enterprises that provide transparency, resiliency, and sustainability across supply chains. SAP’s end-to-end suite of applications and services enables our customers to operate profitably, adapt continuously, and make a difference worldwide.

Kinaxis

Kinaxis is the global leader in modern supply chain management with software that is trusted by renowned global brands to provide the agility and predictability needed to navigate today’s volatility and disruption. It combines Kinaxis patented concurrency technique with a human-centered approach to AI to empower businesses of all sizes to orchestrate their end-to-end supply chain network, from multi-year strategic planning through down-to-the-second execution and last-mile delivery.

Elixum

Elixum marks a new era in operations and supply chain management. With Supply Chain Avatar® and its Unified Core Model, Elixum unites next-generation Advanced Planning & Scheduling capabilities with an AI-powered cognitive engine, enabling decision support and automation at an unprecedented level of performance – for all planning levels, processes, and decision tiers. Its highly flexible and blended cloud-native applications complement, enhance, and integrate with existing systems.

Why CAMELOT

CAMELOT is a recognized leader in supply chain management consulting with a strong track record of creating value within focused assignments as well as in complex supply chain transformations across various industries, powered by a profound understanding of industry trends and innovative strength.

Featured Insights

Render Post Preview here

Contact

Christian Kroschl

Partner OperationsHeads the Consulting Line Supply Chain Management at CAMELOT and helps clients achieve a truly integrated and calibrated supply chain

Markus Geutler

Partner, SCM & OperationsFocuses on transforming the global supply chains of our US based customers.